Leak detection and automatic Pump Down for R410A refrigerant by Panasonic

A complete assurance and safety protection. Ideal solution for hotels, offices and public buildings where the strict safety of end users and workers is required.

The system monitors refrigerant leakage continually and provides a warning, preventing major refrigerant loss and potential damage to the installation’s efficiency. The system can reduce potential refrigerant loss by up to 90%.

As well as ensuring safe and reliable operation, Panasonic’s Pump Down system contributes towards BREEAM POL1 points and enables compliance with current EN 378 standards, covering applications where refrigeration concentration levels exceed practical safety limits of 0,44 kg/m³.

Basic Pump Down function:

Leak detection.

Activate Pump Down process.

Collect refrigerant within receiver tank.

Close valves to isolate refrigerant.

Technical focus:

Compatible with Mini ECOi / ECOi EX / ECO G* Series with R410A refrigerant.

A receiver kit included as standard.

Includes updated controller.

Connection in two ways: 1 - With local room leakage sensors / 2 - Using innovative algorithm.

R22 renewal possible.

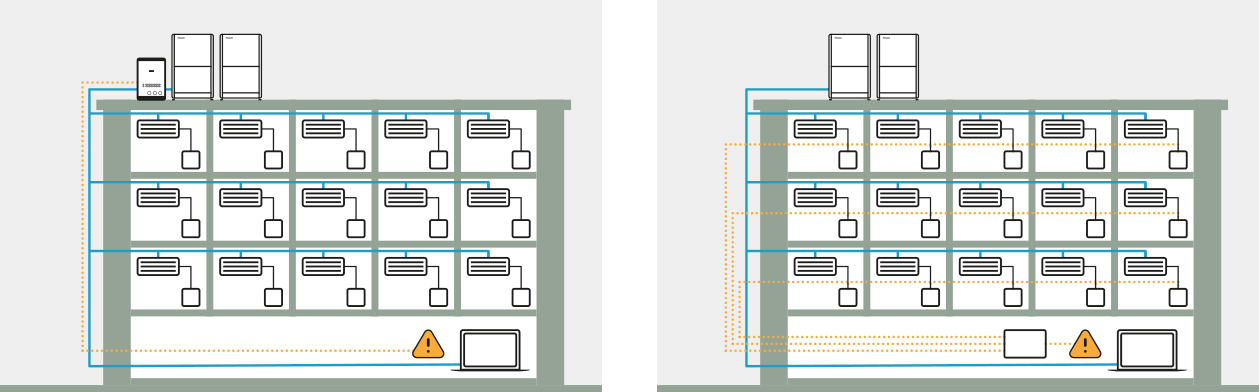

Direct leak detection method: the safest solution for small rooms

The leak detector is connected directly to the indoor unit and the Pump Down system is directly connected to the outdoor unit PCB. The Pump Down system will activate when a leak is detected in the room and initiate a refrigerant reclaim operation immediately. This immediate reaction, and large refrigerant storage capacity, offers very high levels of safety for end users, building occupants, as well as being environmentally friendly.

No additional communication panels or software is required. This option should be implemented in any area that is not compliant with BS EN 378.

Indirect leak detection method: Unique PLC algorithm to determine refrigerant leakage