Old pipes reuse

Notes on Reuse of Existing Refrigerant Piping

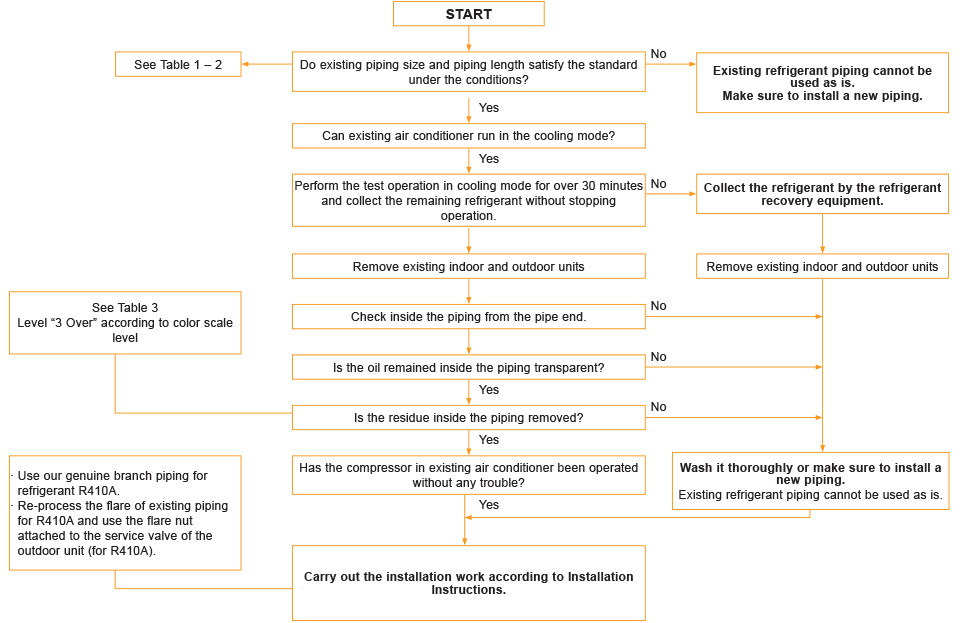

It is possible for each series of PE1 type and PEY1 type outdoor unit to reuse the existing refrigerant piping without cleaning when obtained a certain condition. Make sure that the requirements under the section “Notes on Reuse of Existing Refrigerant Piping”, “Measurement Procedure for Renewal” and “Refrigerant Piping Size and Allowable Piping Length” will be satisfied in order to carry out . Also, check the items with regard to section “Safety” and “Cleaning”.

1. Prerequisite

- If the refrigerant used for the existing unit is other than R22, R407C and R410A, the existing refrigerant piping cannot be used.

- If the existing unit has another use than air conditioning, then existing refrigerant piping cannot be used.

- If there is a hollow, crack or corrosion on the piping, make sure to install new piping.

- If the existing piping is other than capable of reuse of piping as shown in the flowchart, make sure to install new piping.

- In case of multiple operation type, use our genuine branch piping for refrigerant R410A.

3. Cleaning

- When the refrigerant oil used for the existing unit is other than the listed below, make sure to install new piping or wash it thoroughly before reusing it.

[Mineral Oil] SUNISO, FIORE S, MS

[Synthesized oil] alkyl benzene oil (HAB, parallel freeze), ester oil, ether oil (PVE only)

- If the existing pipes in the outdoor and indoor units remain disconnected, make sure to install a new piping or wash it thoroughly before reusing it.

- If the discolored oil or residue remains in the existing piping, make sure to install a new piping or wash it thoroughly before reusing it. See “Deterioration Criteria for Refrigerant Oil” in table 3.

- If the compressor of the existing air conditioner has a failure history, make sure to install a new piping or wash it through thoroughly before reusing it.

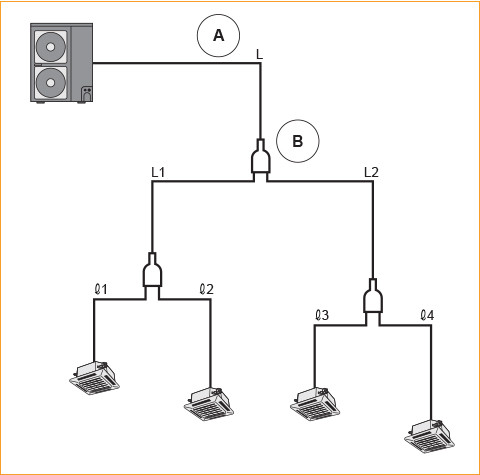

- Alleen de hoofdbuis L kan worden gebruikt met bestaande buizen van verschillende diameters.

- Installatiewerk voor een standaard omvang is geschikt voor L1, L2, ℓ1 - ℓ4 buizen.

- Gebruik alleen onze authentieke aftakkingsbuizen voor het koelmiddel R410A.

Observe the following procedure when reusing the existing piping or carrying out renewal installation work. Flowchart of Existing Piping Measures Criteria for PE1 Type and PEY1 Type Outdoor Unit

Opposite side dimension of flare nut (mm)

Piping size: Ø6.35. For R410A: 22. For R22/R407C: 22.

Piping size: Ø9.52. For R410A: 22. For R22/R407C: 22.

Piping size: Ø12.7. For R410A: 26. For R22/R407C: 24.

Piping size: Ø15.88. For R410A: 29. For R22/R407C: 27.

Piping size: Ø19.05. For R410A: 36. For R22/R407C: 36.

Check if reuse of existing refrigerant piping is possible based on the following chart. The standards other than this one (difference of elevation, etc.) are identical to the requirements of ordinary refrigerant piping.

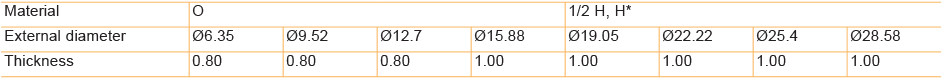

Table 2 - 1 Refrigerant piping size: 3.6 - 14.0 kW type (mm)

In case of type 71, standard size is liquid pipe Ø9.52 / gas pipe Ø15.88.

There is a limitation to liquid pipe Ø9.52 / gas pipe Ø12.7and to liquid pipe Ø12.7 / gas pipe Ø15.88.

However, they are applicable for different diameter’s pipes.

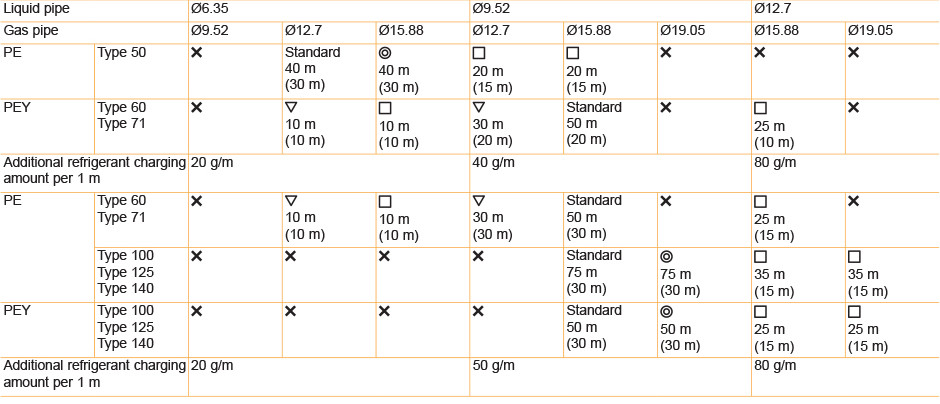

Table 2 - 2 Refrigerant piping size: 20.0 - 25.0 kW type (mm)

- Testen moeten worden uitgevoerd om zeker te stellen dat de olie in het systeem niet zuur is.

- Het merendeel van de testkits zijn acceptabel, waaronder zuigleidingtesten.

- Indien het systeem in het verleden burnouts heeft gehad is het systeem waarschijnlijk niet geschikt voor een vernieuwings-/vervangingstechnologie.